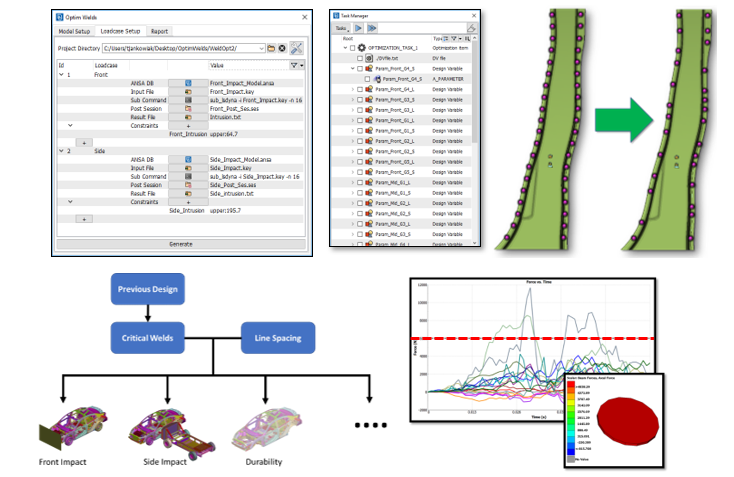

Optimwelds

Optim Welds is a unique multidisciplinary spot weld optimization tool capable of reducing the overall number of welds in a vehicle while meeting the performance targets. The tool allows quick determination of critical weld locations and reduces the insignificant welds. This is done for a particular performance criteria, set for a multitude of load cases. Optim Welds is integrated into ANSA environment which allows easy parametric base-model setup for multiple load cases. The true benefit of Optim Welds comes from being able to quickly determine the critical welds, leading to a faster optimization process over traditional approaches. The result is the best nonuniform weld location distribution with the minimum number of welds required

Function & Features

- Easy and intuitive user interface with a guided process setup.

- Automated multidisciplinary parametric model setup and optimization workflow buildup

- Automated post processing, supporting user defined critical weld criteria

- Reduced number of design iterations resulting in huge computing and time savings

- Nonuniform distribution of welds while meeting the performance criteria

- Continuous reporting of best designs